-

Products

- AC Drives (VFD)

- AC Motors

- Circuit Protection

- Control Panels

- Digital Panel Meters

- Disconnects

- Electrical Enclosures

-

HMI Touch Screens

- Motor Controls

- Power Distribution Blocks

- Power Supplies

- Programmable Controllers

-

Pushbuttons & Indicators

- Shop All Pushbuttons and Indicators

- FMX 22mm Pushbuttons and Indicators

- FMX 30mm Pushbuttons and Indicators

- WEG 22mm Pushbuttons and Indicators

- WEG 30mm Pushbuttons and Indicators

- Chint Monolithic LEDs

- FMX 40mm Beacon Lights

- Auer M22 Beacon Lights

- Pushbutton Stations

- Legend Plates

- Modular Pushbuttons & Indicators

- Pushbutton Enclosures

- Comm Ports & Potentiometers

- Relays and Timers

- Sensors

- Signal Lights

- Soft Starters

- Solar PV Solutions

- Temperature Solutions

- Terminal Blocks

- Transformers

- Wiring Solutions

- Value Add Services

Electrical Enclosures

Widest selection in the industry

FactoryMation offers one of the widest selections of industrial electrical enclosures in the industry. We have partnered with the best enclosure manufacturers in the world to offer a vast array of models in many types, styles, materials, and sizes. Combine this great product selection with our industry leading prices and delivery, and you have an unparalleled value for industrial enclosures. These enclosures protect equipment from harsh industrial environments. Electrical enclosure options vary greatly to suit every need, ranging from polymer to metal and wall-mounted to free-standing.

Wall Mount Enclosures

Shop Wall Mount - Steel

Shop Wall Mount - Stainless Steel

Shop Wall Mount - Non-metallic

- Mild Steel, Stainless Steel, Non-metallic (Fiberglass and Polycarbonate)

- Various hinge styles and latch options

- NEMA/UL Type 1, 3R, 4, 4x, 12, 13 ratings available

- IP55, 56, 65, and 66 ratings available

- Sizes from 6x6x4” to 72x36x16” available

- Many options and accessories

Shop Wall Mount - Steel

Shop Wall Mount - Stainless Steel

Shop Wall Mount - Non-metallic

Free-standing and Floor Mount Enclosures

Shop Free Standing & Floor Mount

- Mild Steel, Stainless Steel, and Fiberglass

- Single-door, Double-door, and Multi-door options

- NEMA/UL Type 3R, 4, 4x, 12, 13 ratings available

- IP55, 56, 65, and 66 ratings available

- Sizes from 6x6x4” to 72x36x16” available

- Many options and accessories

Shop Free Standing & Floor Mount

Modular Enclosures

Modular enclosures offer the greatest versatility and number of design options.

Shop Modular Enclosures

Modular enclosures offer the greatest versatility and number of design options.

- Mild Steel and Stainless Steel (special order)

- Single-door and double-door units

- Combinable units allow for many size and design options

- Open profiles with 25mm hole pattern allow almost limitless choices for accessory location

- NEMA/UL Type 4, 4x, 12, 13 ratings available

- IP55, 65, and 66 ratings available

- 63x24x12” to 87x47x24 unit sizes available

Shop Modular Enclosures

Junction Boxes

Junction Boxes house multiple wires and protect them from accidental damage.

Shop Junction Boxes

Junction Boxes house multiple wires and protect them from accidental damage.

- Polycarbonate and Mild Steel

- Single-door units

- Screw Cover and Hinged Cover

- UL Type 4,4X, 6, 12, 13

- IP66/67 and IK08 ratings available

- All models DIN Rail Mountable

- Sizes from 3x3x2” to 12x12x5” available

Shop Junction Boxes

Operator Interface Enclosures

Operator Interface Enclosures are used to hold Human Machine Interface devices such as touch panels, pushbuttons, selector switches, pilot lights etc.

Shop Operator Interface

Operator Interface Enclosures are used to hold Human Machine Interface devices such as touch panels, pushbuttons, selector switches, pilot lights etc.

- Mild Steel, Stainless Steel, Polycarbonate, and Fiberglass

- Pushbutton interfaces available in 22mm-30mm

- NEMA/UL Type 1, 2, 3, 3R, 4, 4X, 12, 13

- Consoles and consolets

- Computer Workstations, Free standing or Desktop versions

Shop Operator Interface

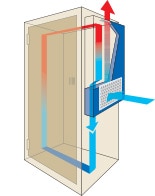

Thermal Management

Thermal Management systems are used to monitoring and control temperature and humidity within an electrical enclosure.

Shop Thermal Management

Thermal Management systems are used to monitoring and control temperature and humidity within an electrical enclosure.

- Thermostats available in 32 to 140° with UL/CE approval

- Condensation Heaters with 240VAC Max and UL/CE approval

- Various Cooling Fans, Vents, Filters and Air Conditioners offered in Indoor UL Type 12 models and Outdoor models with UL Type 4 ratings

- Heat Exchangers, Air to Air, available in Indoor UL Type 12 and Outdoor UL Type 3R, 4 ratings

- Heat Exchangers, Air to Water, available in UL Type 12 ratings.

- Vortex Coolers up to IP66 and Type 4X with CE and UL certifications

Shop Thermal Management

Enclosure Accessories

FactoryMation offers numerous accessories for your enclosure needs.

Shop Enclosure Accessories

FactoryMation offers numerous accessories for your enclosure needs.

- Mounting Panels/ Profiles

- Door/ Latch Options

- Mounting Options: Keys, locks, replacement doors, etc.

- Service/ Replacement Parts

- Protective Accessories: Drip Shields, Removable Wire Covers, etc.

- Lighting Accessories: LED & Fluorescent Lights

- Enclosure Hole Plugs

Shop Enclosure Accessories

Enclosure Cutouts

FactoryMation offers multiple, secure enclosures.

Shop Custom Enclosure Cutouts

FactoryMation offers multiple, secure enclosures.

- Wall Mount

- Free Standing & Floor Mount

- Modular Enclosures

- Junction Boxes

- Operator Interfaces

- Thermal Management Solutions

- Enclosure Accessories

Shop Custom Enclosure Cutouts

What is an Industrial Enclosure?

An industrial enclosure is a metallic or non-metallic housing unit typically used to protect electrical control components and wiring. The enclosure could be made from: steel, stainless steel, aluminum, plastic, or fiberglass. Many enclosure options offer varying degrees of environmental protection from elements such as foreign objects, dust, water, oil, chemicals, and rain as provided with UL/NEMA Type 1, 3, 3R, 4, 12 or 13 ratings and/or ingress protection ratings (IP ratings) of various levels.

Where are Industrial Enclosures Used?

Enclosures are very generic in nature so they can be used almost anywhere protection of electrical and wiring components is required. Some common applications where enclosures are used are:

- Automation Controls

- Building HVAC

- Electrical Switchgear and Junctions

- Food Processing

- Irrigation Control

- Lighting Systems

- Low Voltage Power Distribution

- Machine Tool Systems

- Material Handling Equipment

- Mobile Telecom Systems

- Water Treatment Controls

- WiFi Networks

Who Uses Industrial Enclosures?

Industrial Enclosures are used in many industries. Some industries where the uses of industrial enclosures are prevalent are:

- Building Control

- Process Automation

- Infrastructure

- Alternative & Renewable Energy

- Industrial Control

- Networking/IT

- Marine and Offshore

- Oil & Gas. Food & Beverage

- Pulp & Paper

- Water & Waste Water Treatment

- Air Transportation

- Rail Transportation

- Utilities

FMX

When you see the FMX brand on a product it means you can be assured of high quality and competitive pricing. Most FMX products are produced in the same factories and on the same production lines as many well-known major name brands offered in the market today. All of these products meet or exceed the expected quality and certification requirements in the United States for many industrial applications and undergo stringent testing to ensure they will perform according to standards in the field.

FMX Products Include:

- Wall-mount Enclosures

- Junction Boxes

- Console Enclosures

- Thermal Management Accessories

More about FMX

Saginaw Control and Engineering

With an ever-expanding 310,000 square foot manufacturing facility, located in Saginaw, Michigan, Saginaw Control and Engineering uses state-of-the-art fabricating equipment, including the newest laser cutting and welding technology.

SCE specializes in standard NEMA/UL Type stock electrical enclosures, including NEMA/UL Types 1, 3, 3R, 4, 4X and 12. These enclosures are available in mild steel and stainless steel. They can also customize any of their standard stock enclosures to meet your needs.

Saginaw’s Products Include:

More about Saginaw

With an ever-expanding 310,000 square foot manufacturing facility, located in Saginaw, Michigan, Saginaw Control and Engineering uses state-of-the-art fabricating equipment, including the newest laser cutting and welding technology.

SCE specializes in standard NEMA/UL Type stock electrical enclosures, including NEMA/UL Types 1, 3, 3R, 4, 4X and 12. These enclosures are available in mild steel and stainless steel. They can also customize any of their standard stock enclosures to meet your needs.

Saginaw’s Products Include:

- Wall-mount enclosures

- Free Standing & Floor Mount Enclosures

- Modular Enclosures

- Operator Interface Enclosures

- Thermal Management Accessories

More about Saginaw

Allied Moulded

Founded in 1958 and backed by more than 55 years of knowledge and experience molding non-metallic materials, Allied Moulded Products, Inc. is well established within the electrical industry.

Allied Moulded’s Products Include:

More about Allied Moulded

Founded in 1958 and backed by more than 55 years of knowledge and experience molding non-metallic materials, Allied Moulded Products, Inc. is well established within the electrical industry.

Allied Moulded’s Products Include:

- Fiberglass Wall-mount Enclosures

- Polycarbonate Wall-mount Enclosures

- Fiberglass Free Standing Enclosures

- Fiberglass Pushbutton Enclosures

- Enclosure Accessories

More about Allied Moulded

DSE

DSE prides themselves on manufacturing a diverse variety of polycarbonate enclosure products for fortune 500 companies across the world.

DSE Products Include:

More about DSE

DSE prides themselves on manufacturing a diverse variety of polycarbonate enclosure products for fortune 500 companies across the world.

DSE Products Include:

- Pushbutton Enclosures

- Wall-Mount Polycarbonate Enclosures

More about DSE

Ensto

Ensto endeavors to improve energy efficiency and focus on sustainable development regarding all their products. This includes their industrial wall mount enclosures. Their enclosures are designed and manufactured for long-lasting durability and low impact on the environment.

Ensto Products Include:

More about Ensto

Ensto endeavors to improve energy efficiency and focus on sustainable development regarding all their products. This includes their industrial wall mount enclosures. Their enclosures are designed and manufactured for long-lasting durability and low impact on the environment.

Ensto Products Include:

- Fiberglass Wallmount Enclosures

More about Ensto

ETA

ETA has been producing enclosures and accessories for over 40 years. Starting in 1978, ETA has continually developed innovations for electrical enclosure manufacturing. They use state of the art production technologies and materials to ensure the durability, reliability, and functionality of their enclosures. ETA offers NEMA/UL Types 1 & 12 Free Standing and 1, 3R, 4, 12, & 13 Wall Mount enclosures.

ETA Products Include:

More about ETA

ETA has been producing enclosures and accessories for over 40 years. Starting in 1978, ETA has continually developed innovations for electrical enclosure manufacturing. They use state of the art production technologies and materials to ensure the durability, reliability, and functionality of their enclosures. ETA offers NEMA/UL Types 1 & 12 Free Standing and 1, 3R, 4, 12, & 13 Wall Mount enclosures.

ETA Products Include:

- Wall-mount enclosures

- Free Standing Modular enclosures

More about ETA

How to Select an Enclosure?

We offer a tremendous selection of electrical enclosures and selecting the right enclosure can be daunting. There are many criteria that can be used to select an enclosure. The importance of each of these criteria is dependent on the requirements for your application. Here are a few guidelines to keep in mind when selecting the enclosure that will work best for your application:

We offer a tremendous selection of electrical enclosures and selecting the right enclosure can be daunting. There are many criteria that can be used to select an enclosure. The importance of each of these criteria is dependent on the requirements for your application. Here are a few guidelines to keep in mind when selecting the enclosure that will work best for your application:

Enclosure Size

The required size of an enclosure often depends on the space required for the components you will be installing inside.

1. It is often helpful to do a layout of the control components you will install onto the subpanel of the enclosure. You will also want to consider the maximum depth of the components installed on the subpanel. See Diagram

2. Next you will want to determine any components mounted to the door or body of the enclosure and determine the ingress spacing requirements for those components. See Diagram

3. Once you add the spacing required for subpanel components and the ingress measurements, you should have a good idea of the enclosure size requirements.

Material

Mild Steel: Enclosures composed of hot or cold rolled steel. Mild steel enclosures are extremely durable and modifiable. The powder coat paint finish offers adequate protection for indoor and some outdoor applications. However, mild steel may not be the best choice for corrosion resistance.

Fiberglass: Offers protection against exposure to many harsh chemicals. Fiberglass is also lightweight and strong. Therefore, they possess high impact strength and rigidity. Fiberglass also has some insulating value and can be an advantage or disadvantage when considering heat dissipation.

Stainless Steel: Extremely durable with the advantage of corrosion resistance, thus making them ideal for harsh applications. Stainless steel excels in applications where daily cleaning with harsh chemicals or mild abrasives is required.

Polycarbonate: Composed of thermoplastic flexible resin, polycarbonate enclosures usually boast of light weight, a wide temperature range, and high impact resistance. However, these are not suitable for environments containing strong alkalis or organic solvents.

Environmental Rating

Indoor Installation

You will need to determine the degree of protection required for your installation environment. Some considerations are atmospheric conditions such as the presence of dust, falling or pressurized liquids, and/or high humidity levels. Moderate condensation, which may occur occasionally due to temperature variations, should also be considered. Sometimes special service conditions can exist, and the enclosures must be suitable for each situation.

Degree of Protection Required

The degree of protection provided by any enclosure against ingress of solid foreign bodies and liquid is indicated by the UL Type Rating (based on UL50 and UL50E), NEMA Type Rating (based on NEMA 250), and/or the IP Rating (based on IEC 60529). Most enclosures offered by FactoryMation have UL Type ratings as well as IP ratings. For more information on UL Type ratings or IP ratings you can use the related links to access our knowledgebase.

The degree of protection provided by any enclosure against ingress of solid foreign bodies and liquid is indicated by the UL Type Rating (based on UL50 and UL50E), NEMA Type Rating (based on NEMA 250), and/or the IP Rating (based on IEC 60529). Most enclosures offered by FactoryMation have UL Type ratings as well as IP ratings. For more information on UL Type ratings or IP ratings you can use the related links to access our knowledgebase.

Chemical Agents

In certain installations a high degree of hygiene is needed for which chemical products are used. Good examples of these installations are to be found in the chemical industry and in food processing. For these types of applications, materials such as stainless steel or non-metallic enclosures may be recommended.

In certain installations a high degree of hygiene is needed for which chemical products are used. Good examples of these installations are to be found in the chemical industry and in food processing. For these types of applications, materials such as stainless steel or non-metallic enclosures may be recommended.

Outdoor Installation

Climate Conditions

In outside installations, the enclosure is exposed to rain, wind, etc., and therefore it is necessary to bear these conditions in mind and choose the enclosure with the sufficient ingress protection rating that guarantees that water will not penetrate. Some applications require additional protection such as rain-hoods which help protect the gasket and avoiding possible deterioration. Consideration should also be given to temperature range and condensation.

In outside installations, the enclosure is exposed to rain, wind, etc., and therefore it is necessary to bear these conditions in mind and choose the enclosure with the sufficient ingress protection rating that guarantees that water will not penetrate. Some applications require additional protection such as rain-hoods which help protect the gasket and avoiding possible deterioration. Consideration should also be given to temperature range and condensation.

Geographical Conditions

Depending on the environmental conditions and the geographical situation that the enclosure will occupy, it is possible that the enclosure has to be protected against corrosion (ie. proximity to coast, etc.). Saline or high humidity environments may require the use of stainless steel or non-metallic (fiberglass or polycarbonate) enclosures. In marine environments with a high salinity the use of Stainless Steel 304 is not sufficient. Stainless Steel 316L, has better qualities against corrosion, and ensures the performance of the enclosure. For environments where chemical products are present it is necessary to analyze each case individually since the chemical agents affect stainless steel material in different ways.

Depending on the environmental conditions and the geographical situation that the enclosure will occupy, it is possible that the enclosure has to be protected against corrosion (ie. proximity to coast, etc.). Saline or high humidity environments may require the use of stainless steel or non-metallic (fiberglass or polycarbonate) enclosures. In marine environments with a high salinity the use of Stainless Steel 304 is not sufficient. Stainless Steel 316L, has better qualities against corrosion, and ensures the performance of the enclosure. For environments where chemical products are present it is necessary to analyze each case individually since the chemical agents affect stainless steel material in different ways.

Abrupt Temperature Changes

If the internal temperature of the enclosure is reduced rapidly (which can and does occur under ‘normal’ weather conditions) the pressure inside a high IP rating enclosure may be significantly lower than the ambient pressure outside, thereby inducing a suction effect through the gasket areas. This could result in moisture around the gaskets being drawn into the enclosure. Therefore, consideration should be given to ventilating the enclosure.

If the internal temperature of the enclosure is reduced rapidly (which can and does occur under ‘normal’ weather conditions) the pressure inside a high IP rating enclosure may be significantly lower than the ambient pressure outside, thereby inducing a suction effect through the gasket areas. This could result in moisture around the gaskets being drawn into the enclosure. Therefore, consideration should be given to ventilating the enclosure.

Condensation

Condensation occurs due to differences in temperature between the inner and outer surfaces of the enclosure. Therefore, condensation can also occur on the inner components, which can cause the appearance of corrosion or defects. To avoid condensation, ventilation and/or thermal management can be used.

Condensation occurs due to differences in temperature between the inner and outer surfaces of the enclosure. Therefore, condensation can also occur on the inner components, which can cause the appearance of corrosion or defects. To avoid condensation, ventilation and/or thermal management can be used.

Special Service Conditions

From airborne debris and temperature variations to ultraviolet (UV) rays, environmental elements can have a significant impact on the performance of an enclosure. All electronic equipment needs to be able to withstand the physical demands of the environment in which it is to be used. Some additional environmental considerations include but are not limited to:

1. Abnormal ambient air temperature and humidity may require thermal management products to meet application requirements. FactoryMation offers a large range of thermal management products.

2. Presence of corrosive substances may require special paint or pre-treatment that will endure harsh conditions. Contact FactoryMation for special enclosure paint requirements.

3. Electrical enclosures can be exposed to vibrations in areas such maritime environments, earthquake risk areas, nuclear power plants, military areas. These applications may require special certifications such as vibration tests carried out according to the “Rules for Ships” of Det Norske Veritas Class A by DEKRA. Some enclosures offered by FactoryMation offer these certifications.

4. Some application areas require seismic test certification such as the IEEE Std. 344-1987 Recommended Practice for Seismic Qualification of Class 1E Equipment for Nuclear Power Generating Stations. Contact FactoryMation for enclosures that meet these requirements.

From airborne debris and temperature variations to ultraviolet (UV) rays, environmental elements can have a significant impact on the performance of an enclosure. All electronic equipment needs to be able to withstand the physical demands of the environment in which it is to be used. Some additional environmental considerations include but are not limited to:

1. Abnormal ambient air temperature and humidity may require thermal management products to meet application requirements. FactoryMation offers a large range of thermal management products.

2. Presence of corrosive substances may require special paint or pre-treatment that will endure harsh conditions. Contact FactoryMation for special enclosure paint requirements.

3. Electrical enclosures can be exposed to vibrations in areas such maritime environments, earthquake risk areas, nuclear power plants, military areas. These applications may require special certifications such as vibration tests carried out according to the “Rules for Ships” of Det Norske Veritas Class A by DEKRA. Some enclosures offered by FactoryMation offer these certifications.

4. Some application areas require seismic test certification such as the IEEE Std. 344-1987 Recommended Practice for Seismic Qualification of Class 1E Equipment for Nuclear Power Generating Stations. Contact FactoryMation for enclosures that meet these requirements.

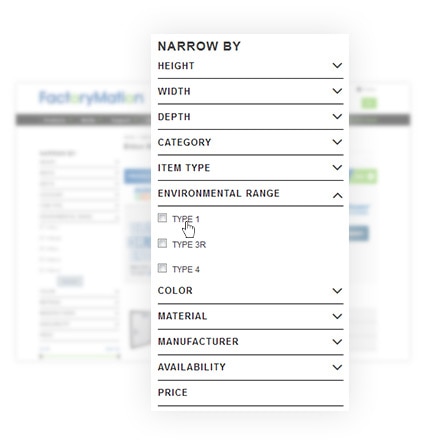

Facet Selection Tool

You can use the facet selection tools on the FactoryMation website to quickly sort through the vast array of enclosures offered and narrow your choices according to the following criteria:

1. Dimensions – Height, Width, Depth

2. Category and Type of Enclosure

3. Environmental Range (ie. UL Type ratings)

4. Color

5. Material

6. Manufacturer

7. Price