Allied Moulded

Product Selection

Allied Moulded Products, Inc. has worked for decades to produce high-quality electrical enclosures. Enclosures from Allied Moulded are prevalent in a variety of markets and are ideal for industrial settings. Focused on nonmetallic materials, these enclosures are either polycarbonate or fiberglass. All models feature UV protection and stainless-steel hardware. Most Allied Moulded enclosure models are non-corrosive, non-conductive, nonflammable, and temperature-resistant. Enclosures are available in a variety of sizes ranging from small junction boxes up to large free-standing enclosures and include UL Types 1, 2, 3, 3R, 4, 4X, 12, and 13. FactoryMation offers the following Allied Moulded enclosure series:

Allied Moulded Products, Inc. has worked for decades to produce high-quality electrical enclosures. Enclosures from Allied Moulded are prevalent in a variety of markets and are ideal for industrial settings. Focused on nonmetallic materials, these enclosures are either polycarbonate or fiberglass. All models feature UV protection and stainless-steel hardware. Most Allied Moulded enclosure models are non-corrosive, non-conductive, nonflammable, and temperature-resistant. Enclosures are available in a variety of sizes ranging from small junction boxes up to large free-standing enclosures and include UL Types 1, 2, 3, 3R, 4, 4X, 12, and 13. FactoryMation offers the following Allied Moulded enclosure series:

Company Information

Founded in 1958 and backed by more than 55 years of knowledge and experience molding nonmetallic materials, Allied Moulded Products, Inc. is well established within the electrical industry. They’re committed to providing products that prevent damaging elements such as water, salt, chemicals, and UV from threatening your equipment. Their selection of UL- and IEC-rated fiberglass and polycarbonate enclosures provides maximum protection where you need it most.

Skilled Manufacturing Process

Allied Moulded has grown to become the benchmark of quality within the electrical enclosure industry. Their full-service molding operation includes expertise in compression and injection molding, use of thermoset and thermoplastic materials, and a unique resin transfer molding process. Utilizing a modern, automated assembly process, Allied Moulded is pleased to provide their customers with a superior product at a competitive price. Allied Moulded is unique among enclosure manufacturers as they are vertically integrated from mold design and fabrication to product delivery. On-site molding, assembly, and warehousing located in the heart of the country enables them to produce a high-quality product while delivering quick turnaround on standard orders. Allied Moulded can also provide timely delivery on enclosure modifications including holes, cutouts, and special colors.

Patented Innovations

Allied Moulded operates a modernized production facility in the United States dedicated to manufacturing non-metallic enclosures. Spearheading the industrial market with their unique designs and revolutionary formulas, Allied Moulded has developed an unprecedented formula to further protect their enclosures. Their ULTRAGUARD® finish is fiberglass reinforced polyester (FRP) material. Their Material Research and Development laboratory successfully optimized ingredients to create a formulation with the ability to resist the effects of UV degradation. The formulation was developed through the effective use of UV absorbers, HALS (Hindered Amine Light Stabilizers), and antioxidants. Together, all three classes of stabilizers provide specific protection to modes of failure associated with outdoor exposure.

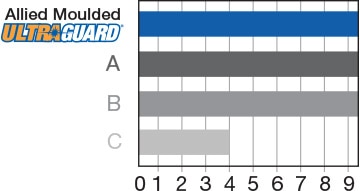

ULTRAGUARD® vs. The Competition

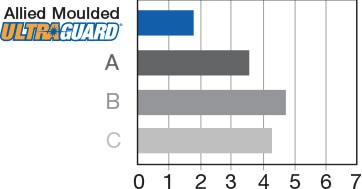

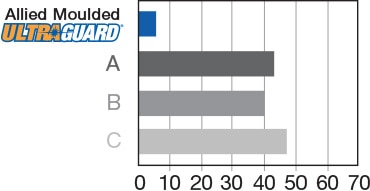

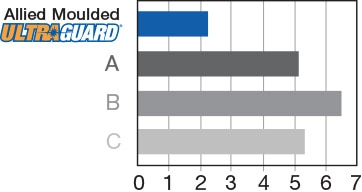

Allied Moulded’s ULTRAGUARD® formulation outperformed materials used by three leading fiberglass enclosure manufacturers. The following four key areas were benchmarked, and ULTRAGUARD® easily came out on top:

Yellowing

|

Change in Gloss

|

Discoloration

|

Fiberbloom Resistance

|